Our Equipment

Steinwall has the right equipment to serve all of our customers’ plastic injection molding needs.

Efficient production methods

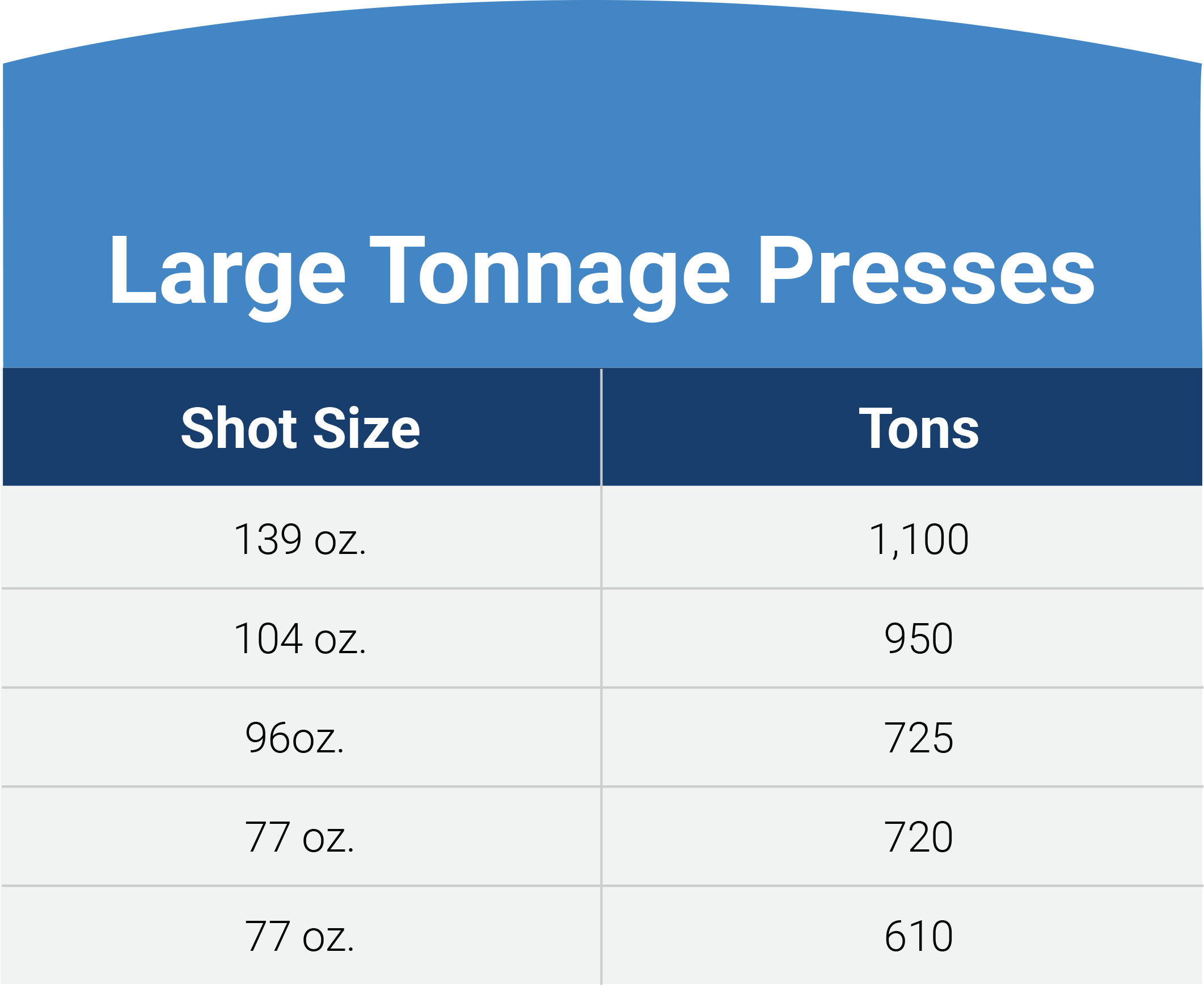

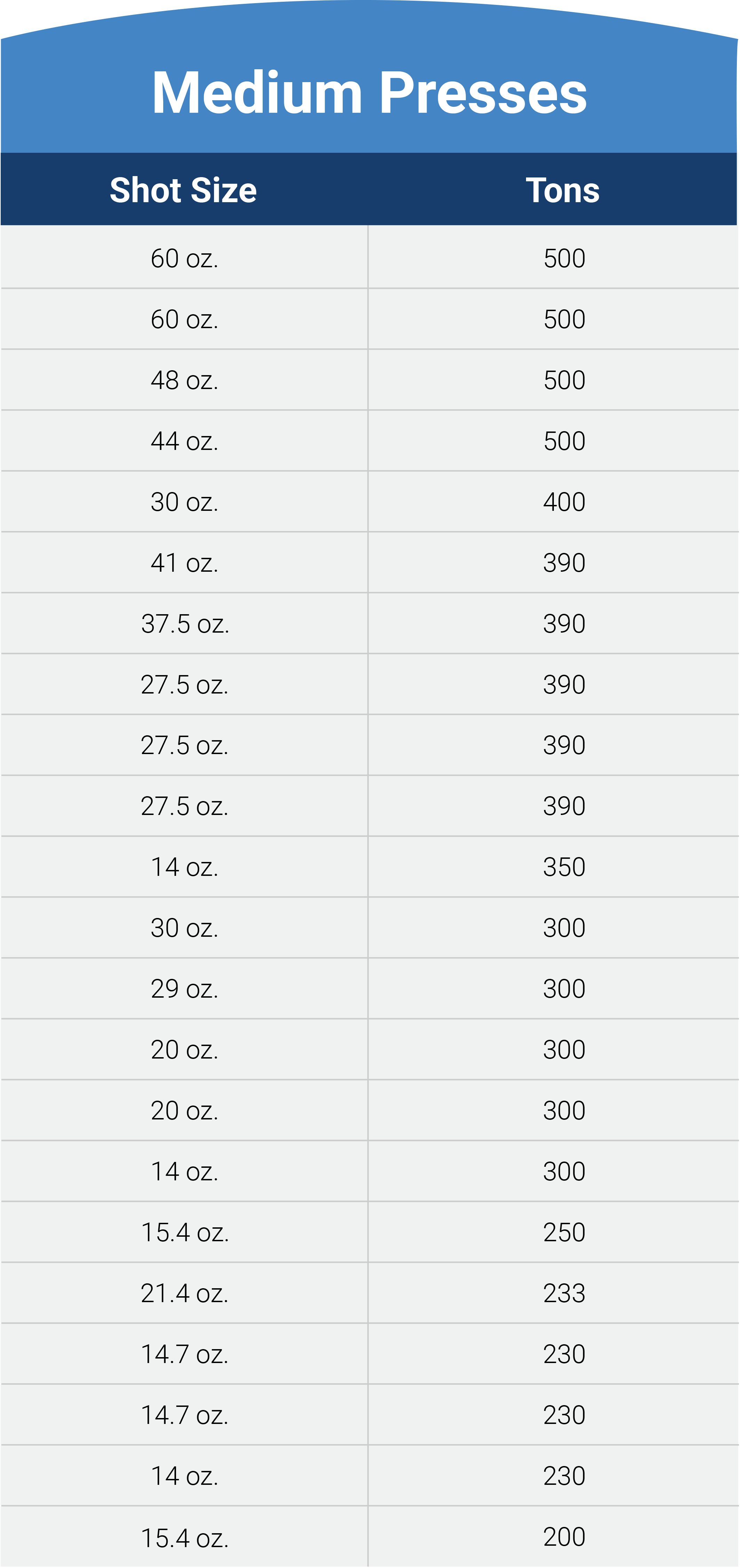

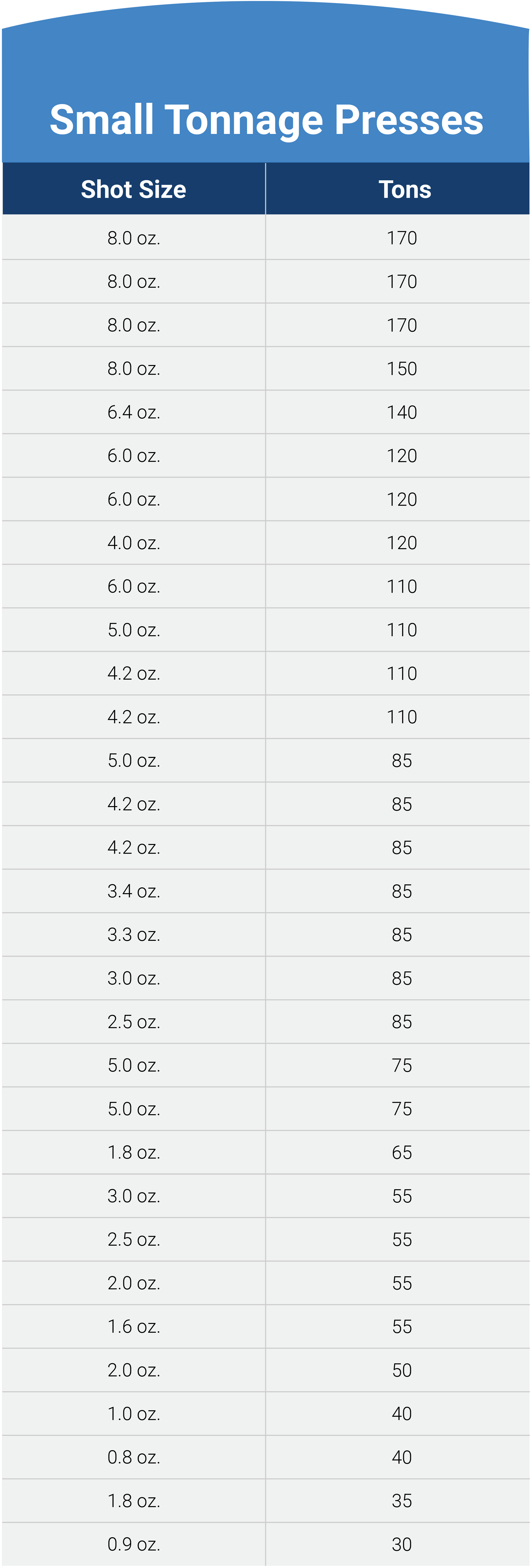

The Steinwall Plastic Injection Molding facility in Minneapolis, Minnesota currently houses 58 plastic injection molding presses ranging in size from 30 to 1,100 tons, including horizontal and vertical varieties. Steinwall’s variety of press sizes gives customers a number of manufacturing options and allows the most efficient production methods to be applied to their projects.

In addition to the many plastic injection molding presses, Steinwall maintains a host of supporting capabilities by using state of the art equipment throughout the facility used in every step of our process. We continually invest in improving the tools and equipment our employees need, including initial concepting and design technologies, precision Tool Room machines, post-production equipment for material handling, quality control, finishing operations and sophisticated warehousing and distribution systems.

Assembly and Secondary Operations

Assembly

Sonic welding

Pad printing

Drilling

Taping

Packaging

Inspection and Quality Control

Cordax CMM running PC-DMIS

Romer Absolute Arm running PC-DMIS

Optical Comparator

Design and Engineering

Solidworks

LulzBot TAZ 6 3D printer

CAD

Tool

Room

Charmilles Roboform 20

Milltronics Partner MM18 (CNC)

Chevalier Sinker EDM

Bridgeports with Digital Readouts (5)

Bridgeports (2)

Surface Grinders (5)

Deckel Engraving Machine

Lathe

Band Saws (2)

Radial Drill

Tig Welder

Vapor Blaster

Numerex Height Gauge

CadKey Computer Workstations (2)

Heat Treating Oven

Warehouse and Shipping

Forklifts

Pallet Wrappers

Barcode and Scan Gun Technology

Electronic Scales

763.767.7060

1.800.229.9199

1759 116th Avenue

Minneapolis, MN 55448

Follow Us

Services